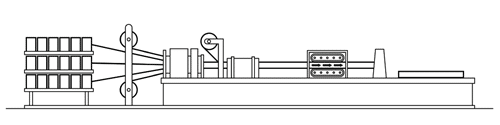

Tinby is the pleased to announce the opening of their new 1,100 sq.m. plant in Latvia - where we will focus on the manufacture and distribution of pultruded products to our customers.

With a manufacturing hall of just over 1,100 sq.m., Tinby will be well-equipped to begin manufacturing composite profiles using pultrusion at our new facilities in Latvia - under the name Tinby SIA.

What is pultrusion?

Pultrusion is a process whereby thick fibres are pulled continuously through a tool, which ensures that the threads generate the geometric cross-section desired for that particular profile. The fibres are impregnated with a resin, which then undergoes a thermosetting process, creating a solid, shaped profile, which can subsequently be sawn off into the desired lengths. The profile can be shaped and optimized during several stages in the process, e.g. according to the attributes of the material, which are primarily regulated through the type and number of fibre threads used. To put it simple pultrusion can be described as woven and reinforced fibre threads that are shaped into the geometry and strengths, which you need. The production method ensures consistent quality, which can be reproduced.

Combining different types of resin treated fibres allows us to design the finished profile in the exact strengths and stiffness you desire, regardless of whether these items are to be used within the transportation, car, wind, construction, sanitation or navy industries; or it could be used for something completely different.

Versatility is the key in our production halls

In addition to constantly developing pultrusion technology, Tinby also actively develops new products in collaboration with our clients. Therefore, we will be working closely with our clients at our Latvian plant to produce any type of profile they could possibly need, where a high degree of strength is required. This is particularly relevant in the wind energy sector which requires materials with long lifespans, and that are extremely strong, hard-wearing and resistant to the weather conditions. Tinby’s construction profiles fit the bill here, and live up to the stringent requirements that apply, making them the obvious choice for wind turbine elements for clients all over the world.

What are the advantages of using pultrusion?

As the final pultruded product is made of a composite material, i.e. a combination of different materials, one of the primary and most important advantages is that the items produced are much stiffer and stronger in relation to their density - compared to a large number of other materials. In many cases, plastic composites can thus replace materials such as aluminium, where, as we all know, continuous maintenance is a necessary evil.

In comparison, composite items require only minimal maintenance. Other significant advantages offered by pultruded products are that the composites can be moulded or shaped into lightweight components that have a complex geometry, are lightweight and highly flexible. Due to the minimal maintenance involved, their high durability and longer lifetime, there are a lot of savings to be made when using Tinby’s composite solutions.